Industrial equipment is used for a variety of different applications. Because it is mobile, it works under many different conditions, and stopping and slowing down is an essential part of its operation. Although there are many different types of braking systems, hydraulic brakes are the most effective in certain situations. Learn more about these advantages and disadvantages of hydraulic braking systems. You might also find hydraulic brakes beneficial in your next job application. The pros and cons of hydraulic braking systems will help you choose the right one for your needs.

Disadvantages of hydraulic brakes

The advantages of hydraulic brakes are its power and accuracy. It is also easier to maintain. However, this type of braking system has a few disadvantages. In addition to the messiness of the fluid, it can be caustic to paint and some types of seals. In addition to this, it can become useless if the fluid leaks or breaks. Air brakes are another alternative, and they use compressed air to control braking power.

Reliability

Reliability of hydraulic brakes has become an important issue in modern automotive technology. The system works by applying pressure through tubing to the wheel cylinders. Depending on the type of system, there are several ways to ensure its reliability. Hydraulic brakes are the most reliable type of brake system. They provide superior braking performance and are more reliable than manual systems. They also require little effort for operation.

Power

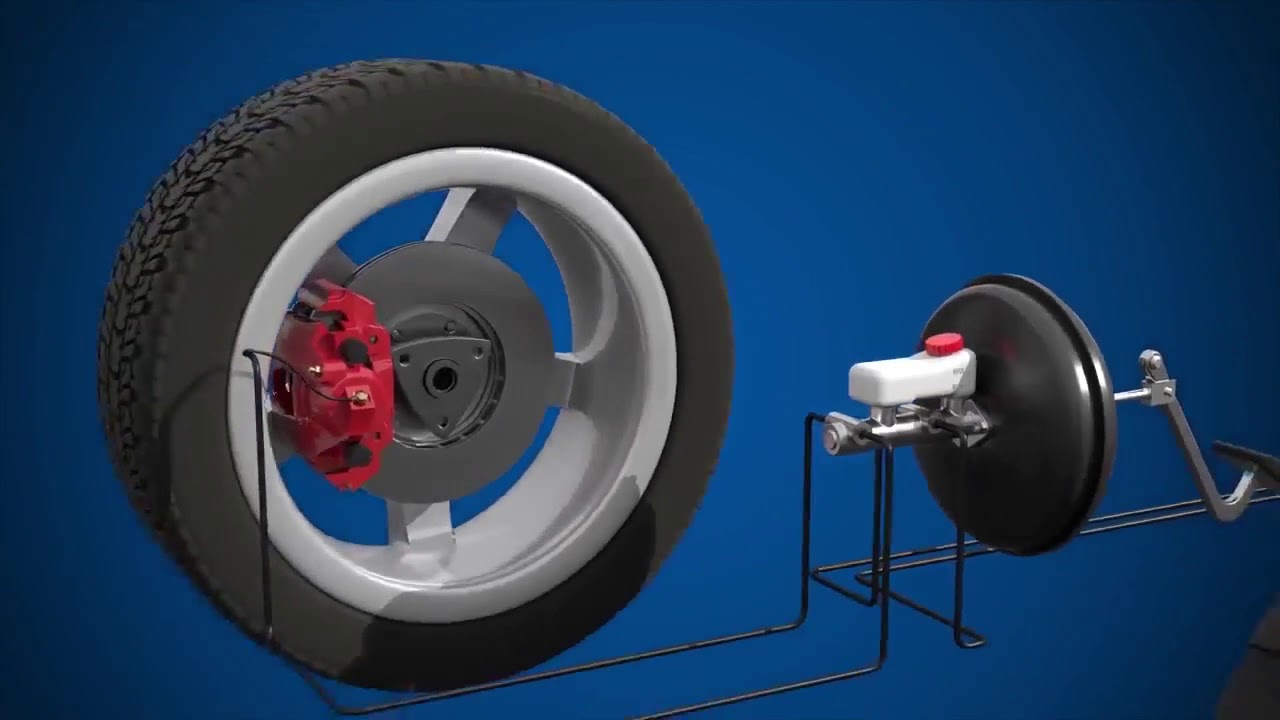

If you’re looking for a brake system that offers power and control, look no further than hydraulic brakes. Hydraulic brakes offer power and control through a lever-pump design. These powerful brakes provide equal pressure across the entire braking surface. A master piston is positioned on the front of the cylinder and connected to the brake pedal via a lever. When the brake pedal is pressed, the lever multiplies the force to increase the force on the master piston. The master piston must move three times the distance of the pedal in order to force the brake pad.

Efficiency

There are many factors that determine the efficiency of hydraulic brakes. The braking force generated by each axle is the most important parameter, followed by the air pressure system and the symmetry and variation of braking efficiency. These parameters are used to calculate the braking ratio and vehicle weight. Improper axle load and excessively low vehicle weight have significant effects on the symmetry and variation of the braking efficiency. A correct evaluation should take all these factors into consideration.

Oil/fluid leakage

The main advantage of hydraulic brakes is their superior performance and longevity. However, these brakes are not without their drawbacks. They require a considerable amount of maintenance, including periodic checks for leakage, and changing of the fluid as needed. This can be expensive and time-consuming, but the benefits far outweigh these drawbacks. Below are some of the common reasons why hydraulic brakes are superior to other types of brakes.

Maintenance

Hydraulic brakes offer several maintenance advantages over conventional disc brakes, such as ease of maintenance and easy replacement of rotors and pads. However, the rotors can become rusted or warped over time, resulting in uneven wear and poor performance. To ensure proper performance and prevent further damage, you should regularly check brake pads and rotors with a rag. If you see any signs of wear, use an adjustable wrench to gently hammer out any loose rotors or pads. Never touch the brake rotors with your fingers; oil on your fingers will reduce the braking power.